Kayakocvib KVM series

back.jpg)

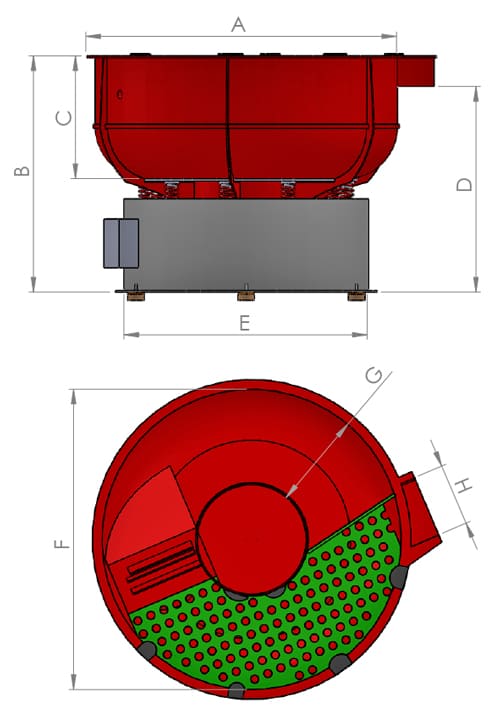

KVM series, Circular Type of Vibrators

KVM – Circular Type of Vibrators series round vibratory finishing machines are used for deburring and polishing the surfaces of all metal and non-metal materials and for making precise polishing and minimizing surface roughness. Vibratory bowl sizes are classified based on volume (liter). The appropriate bowl volume is selected according to the geometric structure of the parts and daily production quantity.

ADVANTAGES OF KVM SERIES

- Grinding and polishing in minimum time thanks to bowl design.

- Vibration impact can be reduced or increased mechanically (by weight).

- Easy to separate stone and material used in models with sieve and ramp.

- It allows the use of different sizes of stones thanks to the easily removable portable sieve.

- Thanks to its conformable ramp design, all materials are easily unloaded from the bowl.

- Our high-performance vibration motor is long-lasting and minimizes your service costs.

- Resistance to acidic environments with double layer epoxy paint.

- Long bowl life thanks to our abrasion-resistant Elastomer type (90 Shore) polyurethane coating.

- Custom-design bowl or chassis height and spring design.

- Noise level is minimized with the optional Pneumatic Acoustic cover. Remote control of the pneumatic ramp lever from the control panel is available as an option.

- As the vibration level can be adjusted with our speed-controlled panels, the most precise surface finishing is ensured on metal and non-metal surfaces.

- All electrical panels are produced in accordance with CE norms.

- Minimum consumption of liquids used in degreasing, deburring, and polishing processes is ensured by means of dosing pump.

- KVM Series electrical panels can work in accordance with automation systems with PLC software.

- KVM Series can be integrated into the press lines that are continuously producing and work automatically.

- All parts used in our machines are selected according to EU standards.

| DESCRIPTION | KVM15 | KVM40 | KVM120 | KVM220 | KVM420 | KVM720 | KVM1000 |

| Total volume of bowl (lt) | 18 | 43 | 130 | 280 | 490 | 830 | 1200 |

| Capacity (lt) | 8 | 25-35 | 70-90 | 220 | 300-350 | 400-550 | 700-850 Max. |

| Size of work piece (mm) | 90 | 120 | 160 | 180 | 240 | 320 | 360 |

| Bottom P.U. layer of the bowl (mm) | 10 | 10 | 15 | 15 | 15 | 20 | 25 |

| Side wall P.U. layer of the bowl (mm) | 8 | 8 | 12 | 13 | 15 | 18 | 20 |

| Diameter of working bowl (mm) | 410 | 565 | 852 | 1150 | 1355 | 1600 | 1785 |

| Engine power (kW), 380V / 50Hz | 0,17 | 0,35 | 1,1 | 1,7 | 2,2 | 4 | 11 |

| Engine (RPM) | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 |

| Separating ramp | – | – | Optional | Optional | Optional | Optional | Optional |

| Dosage pump (5 lt / 7bar) | Standart | Standart | Standart | Standart | Standart | Standart | Standart |

| Noise isolating cover | Optional | Optional | Optional | Optional | Optional | Optional | Optional |

| Weight (kg) | 42 | 100 | 225 | 460 | 780 | 1270 | 1770 |

| DIMENSIONS | KVM15 | KVM40 | KVM120 | KVM220 | KVM420 | KVM720 | KVM1000 |

| A | 410 | 565 | 852 | 1150 | 1355 | 1600 | 1785 |

| B | 520 | 680 | 791 | 1000 | 1000 | 1200 | 1450 |

| C | 200 | 276 | 315 | 430 | 480 | 595 | 685 |

| D | – | – | 658 | 830 | 820 | 1050 | 1100 |

| E | 330 | 400 | 600 | 855 | 950 | 1300 | 1340 |

| F | 345 | 525 | 780 | 1020 | 1235 | 1460 | 1650 |

| G | 130 | 228 | 284 | 300 | 380 | 445 | 485 |

| H | – | – | 200 | 320 | 270 | 380 | 380 |

video

photo

.jpg)

.jpg)

.jpg)

.jpg)

.jpeg)

.jpg)