Volter Series L

back.jpg)

The VOLTER L series CNC Routers offer a wide range of options and configuration to exactly meet customer needs.

These machines have large selection of processing area from 1,610*1,610mm to 8,200*2,150mm. They are flexible and professional solution for any business.

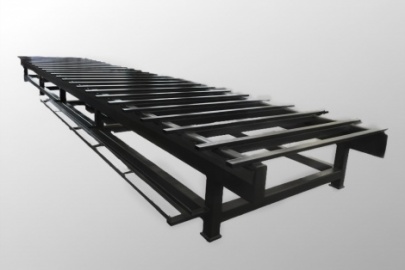

Due to the heavy steel frames with thermal stabilization and high accuracy processing of steel frames by 5-axis machining center, these machines keep high accuracy of processing for all sizes of processing areas.

| Controller | VOLTER CS |

| Max travel speed on X and Y axes, mm./sec. | 500 |

| Max travel speed on Z axis mm./sec. | 100 |

| Max thickness of material , mm. | 160 |

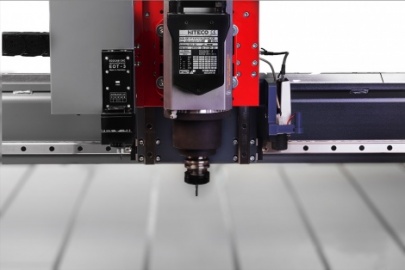

| Spindle power, kW | from 4.5 to 10 |

| Spindle rotation speed, RPM | from 1 000 to 24 000 |

| Tool clamping | Mechanical or pneumatic |

| Type of drives for X and Y axes | Servo, planetary gear heads, helical racks |

| Type of drive for Z axis | Servo, ball screw |

| Control panel | 15" touch monitor |

| Model | Processing area | Dimensions | Weight, kg |

|---|---|---|---|

| VOLTER L1616 | 1 610* 1 610 mm | 2 700 * 2 100 * 1 600 mm | 900 |

| VOLTER L2016 | 2 200 * 1 610 mm | 3 300 * 2 100 * 1 600 mm | 1 200 |

| VOLTER L3016 | 3 200 * 1 610 mm | 4 300 * 2 100 * 1 600 mm | 1 500 |

| VOLTER L3020 | 3 200 * 2 150 mm | 4 300 * 2 600 * 1 600 mm | 1 800 |

| VOLTER L4016 | 4 200 * 1 610 mm | 5 300 * 2 100 * 1 600 mm | 1 800 |

| VOLTER L4020 | 4 200 * 2 150 mm | 5 300 * 2 600 * 1 600 mm | 2 200 |

| VOLTER L6016 | 6 200 * 1 610 mm | 7 300 * 2 100 * 1 600 mm | 2 600 |

| VOLTER L6020 | 6 200 * 2 150 mm | 7 300 * 2 600 * 1 600 mm | 3 100 |

| VOLTER L8020 | 8 200 * 2 150 mm | 9 300 * 2 600 * 1 600 mm | 4 000 |

Basic configuration:

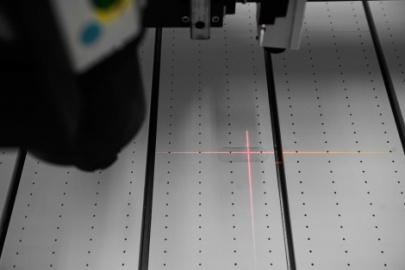

- Vacuum table

- Tool length sensor

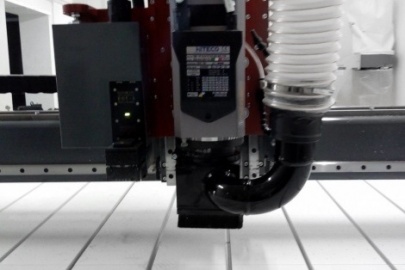

- Brush foot

- Laser pointer

Options:

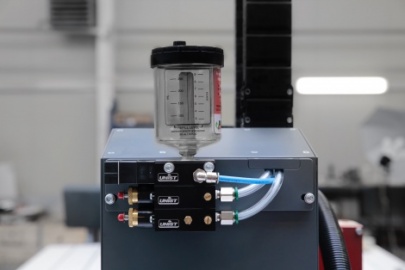

- Tool lubricator

- Vacuum pump

- Automatic tool changer

- Dust collector 3kW with 2 bags

- Dust collector MasterVac TS220

- Tangential knife

- IP camera

- Extended Z axis clearance

- Drag knife

- Vectric VCarve Pro software

video

photo

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.png)

.jpg)