Volter Series M

back.jpg)

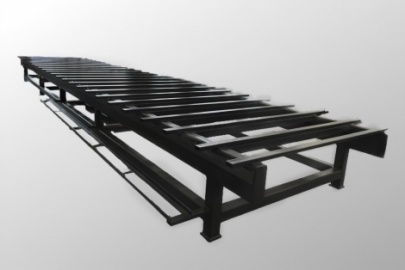

M series machines are represented by 3 versions of tables with the size of the processing area 2,200*1,610 , 3,200*2,150mm and 4,200*2,150mm.

This is the best budget solution for small companies and new businesses. Despite the limited range of options, the M-series equipment is designed and manufactured in strict accordance with VOLTER quality standards.

Machines of this serie are assembled on a heavy steel frame, the size of processing area allows to process almost all sheet materials: aluminum, composite, plastics, MDF, plywood.

| Controller | VOLTER CS |

| Max travel speed on X and Y axes, mm./sec. | 500 |

| Max travel speed on Z axis mm./sec. | 100 |

| Max thickness of material , mm. | 160 |

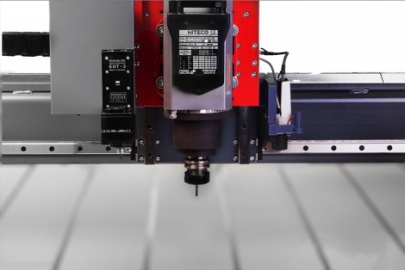

| Spindle power, kW | 4.5 |

| Spindle rotation speed, RPM | from 1 000 up to 24 000 |

| Tool clamping | Mechanical |

| Type of drives for X and Y axes | Servo, planetary gear heads, helical racks |

| Type of drive for Z axis | Servo, ball screw |

| Control panel | External monitor |

| Model | Processing area | Dimensions | Weight, kg |

|---|---|---|---|

| VOLTER M2016 | 2 200 * 1 610 mm | 2 800 * 2 100 * 1 600 mm | 1 200 |

| VOLTER M3020 | 3 200 * 2 150 mm | 3 800 * 2 600 * 1 600 mm | 1 800 |

| VOLTER M4020 | 4 200 * 2 150 mm | 4 800 * 2 600 * 1 600 mm | 2 200 |

Basic configuration:

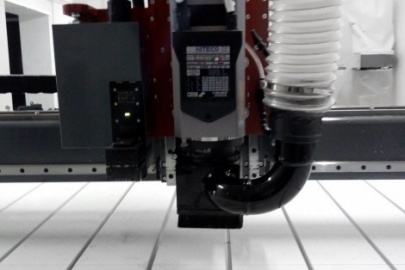

- Vacuum table

- The tool length sensor

- Nozzle for chip removal

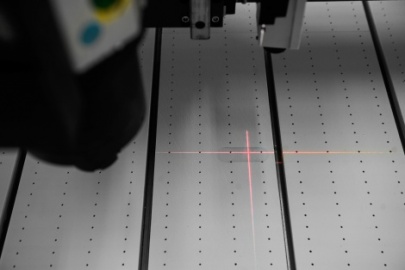

- Laser pointer zero point

Options:

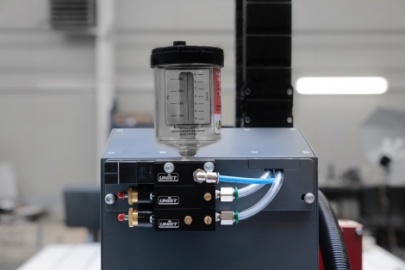

- Lubrication system-tool cooling

- Vacuum pump

- Dust collector 3kW with 2 bags

- Dust collector MasterVac TS220

- Drag knife

- Software Vectric VCarve Pro

video

photo

.jpg)

.jpg)

.jpg)