Volter Series S

back.jpg)

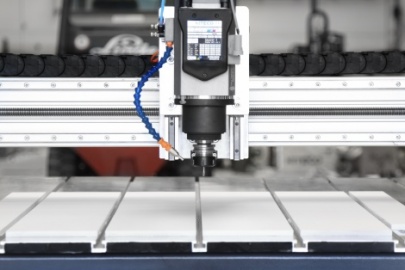

VOLTER S series CNC Routers have processing area 1,030 * 935 mm. This is the ideal solution for the production of small parts.

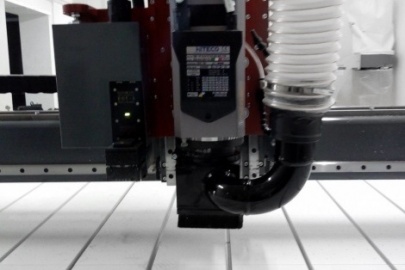

These machines allow to perform milling, cutting, drilling, 3D-processing of parts from non-ferrous metals, plastics, MDF, plywood, wood. Due to the heavy welded steel frame and servo drives on all axes, these CNC Routers have the highest precision.

| Controller | VOLTER CS |

| Max travel speed on X and Y axes, mm./sec. | 150 |

| Max travel speed on Z axis mm./sec. | 100 |

| Max thickness of material , mm. | 100 |

| Spindle power, kW | 4.5 to 6.6 |

| Spindle rotation speed, RPM | from 1 000 to 24 000 |

| Tool clamping | Mechanical or pneumatic |

| Type of drives for X and Y axes | Servo, ball screw |

| Type of drive for Z axis | Servo, ball screw |

| Control panel | 10" touch monitor |

| Model | Processing area, mm | Dimensions, mm | Weight, kg |

|---|---|---|---|

| VOLTER S100 | 1030 * 935 mm | 1 730 * 1 710 * 1 400 mm | 500 |

Basic configuration:

- Vacuum table

- Tool length sensor

- Brush foot

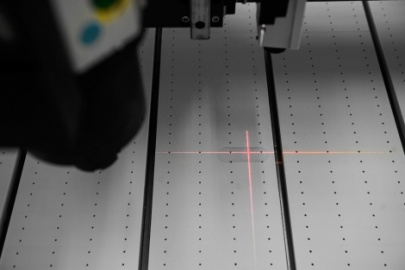

- Laser pointer

Options:

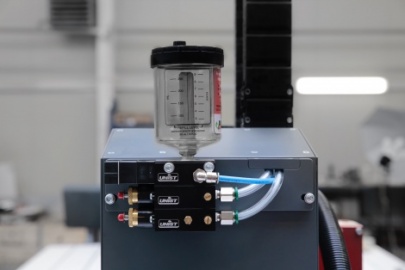

- Tool lubricator

- Vacuum pump

- Automatic tool changer

- Dust collector 3kW with 2 bags

- Dust collector MasterVac TS220

- Vectric VCarve Pro software

video

photo

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)