Thunder Laser Aurora

back.png)

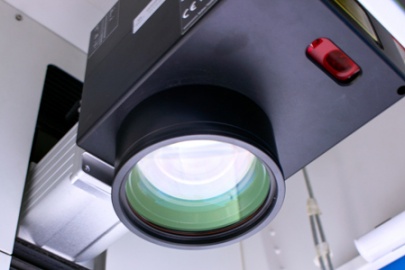

Aurora-Marking Machine

Optical fiber laser engraving machine with fully enclosed cover can be used for marking metal and non-metal materials. It can mark time, date, text, serial number and part number, company logo, icon, symbol, bar code, 2D code, matrix and vector font on all planar, painting, powder coating, anodizing, electroplating metal surfaces, whether they are flat or curved It's still a cylinder.

| Fiber system | AURORA 8 | AURORA 8 PRO | ||

| Marking area | 4.3"×4.3"/110×110mm | 5.9"×5.9"/150×150mm | ||

| Max work Height | 7.9"/200mm | 5.7"/145mm | ||

| Max marking speed | 2m/sec, 200cps | 8m/sec, 800cps | ||

| Z-axis | Motorized Z-axis, 15.4"/390mm | |||

| Table | Alumina table, 14.2"×10.5"/360×265mm | |||

| Net weight | 71kgs/157bs | 72kgs/159lbs | ||

| Housing dimensions(W*D*H) | 27.7"×17"×32"/703mm×430mm×812mm | |||

| Frequency | 20W 20-60kHz |

50W 50-100kHz |

20W(MOPA) 1-4000kHz |

|

| Pulse width | 110ns | 2-350ns | ||

| Cooling | Air cooled | |||

| Red dot pointer | Laser Power<1mW, 630-680nm | |||

| Software | EzCad2 | EzCad3 | ||

| Optional T-theta lenses | 5.9"×5.9"/150×150mm | 7.9"×7.9"/200×200mm | 4.3"×4.3"/110×110mm | 7.9"×7.9"/200×200mm |

| Materials | apply |

| Metallic materials | √ |

| Rigid plastics | √ |

| Hardware tools | √ |

| Industrial accessories | √ |

| Stainless steel | √ |

| Carbon steel | √ |

| Aluminium | √ |

| Iron | √ |

| Steel | √ |

video

photo

.png)

.jpg)

.jpg)

.jpg)