Thunder Laser ODIN

back.jpg)

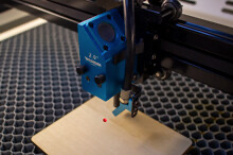

Odin – laser engraver.

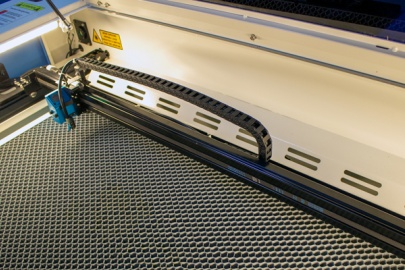

A Thunderlaser new product in 2020, the Odin series laser machine combines small size, compact, high quality engraving and cutting at a low cost. With 5G acceleration and 80 IPS (2000mm/sec) engraving speed, it provides a super fast laser engraving solution for industry. The RF tube allows fantastic beam signature and is air cooled, you don’t have to worry about a water chiller. The gantry payload is minimal and is super smooth.

| Laser System | Odin 22 | Odin 32 | ||

|---|---|---|---|---|

| Laser Tube Wattage | 30 Watt | 60 Watt | ||

| Working Area | 559 x 381 mm (22″ x 15″) | 813 x 508 mm (32″ x 20″) | ||

| Table Size | 625 x 440 mm (24.6″ x 17.3″) | 899 x 567 mm (35.4″ x 22.3″) | ||

| Max Part Size(W x L x H) | 625 x 440 x 190mm(24.6″ x 17.3″ x 7.5″) | 879 x 567 x 190mm(34.6″ x 22.3″ x 7.5″) | ||

| Dimensions(W x D x H) | 1030 x 860 x 1090mm (40″ x 34″ x 43″) | 1284 x 987 x 1090mm (51″ x 39″ x 43″) | ||

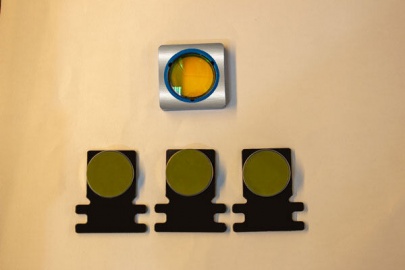

| Laser Type | Radio Frequency Laser Tube | |||

| Cooling | Air Cooled | |||

| Maximum Speed | 2000MM/S | |||

| Maximum machining size at 1000 speed – lightweight laser head | 529 x 381 mm(20.8″ x 15″) | 783 x 508 mm(30.8″ x 20″) | ||

| Maximum machining size at 2000 speed – lightweight laser head | 461 x 381 mm(18″ x 15″) | 715 x 508 mm(28″ x 20″) | ||

| Speed and Power Control | Computer or manually controlled speed and power from 0-100%.Vector color mapping sets speed and power settings using RGB color mapping. | |||

| Operating Modes | Optimized raster,vector,and combined mode | |||

| Resolution(DPI) | User controlled from 100 to 1000DPI(standard laser head) | |||

| Computer Interface | Ethernet and USB Connection | |||

| Compatible Operating Systems | Windows, Mac, and Linux (Mac and Linux with LightBurn Software) | |||

| Buffer Memory | 128MB Standard | |||

| Display Panel | 3.5″ LCD panel showing current file, total working time, laser power, speed, etc… | |||

| Electrical Requirements | Requirements110 to 240 volts,50 or 60 Hz,single phase | |||

| Z-Axis Height | 185mm (7.3″) | 185mm (7.3″) | ||

| Net Weight | 145kgs (320lbs) | 167kgs (368lbs) | ||

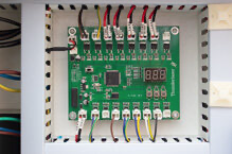

| Motion Control System | High-Speed Stepper Motors | |||

| Speed and Power Control(engraving depth) |

Computer or manually controlled speed and power from 0-100%. Vector color mapping sets speed and power settings using RGB color mapping. |

|||

| Operating Modes | Optimized raster, vector, and combined mode | |||

| Ventilation System | Integral exhaust fan. There is 1 output port, 5.7″ (145 mm) in diameter in the rear of the case. | |||

| Max. Speed | 2000mm/s | |||

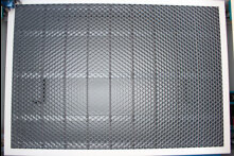

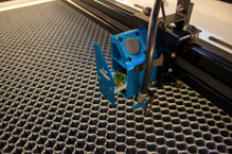

| Workpiece table | Solid metal blades & Honeycomb table | |||

| Max. table load | 20kg / 44lbs | |||

| Materials | Engrave | Cut |

| Wood | √ | √ |

| Acrylic | √ | √ |

| Delrin |

√ |

√ |

| Cloth |

√ |

√ |

| Leather | √ | √ |

| Mat Board | √ | √ |

| Melamine |

√ |

√ |

| Paper | √ | √ |

| Mylar | √ | √ |

| Pressboard | √ | √ |

| Rubber | √ | √ |

| Wood Veneer | √ | √ |

| Fiberglass | √ | √ |

| Plastic | √ | √ |

| Cork | √ | √ |

| Corian | √ | √ |

| Twill | √ | √ |

| Anodized Aluminum | √ | X |

| Painted Metals | √ | X |

| Tile | √ | X |

| Glass | √ | X |

| Coated Metals | √ | X |

| Ceramics | √ | X |

| Marble | √ | X |

| Stainless Steel | * | X |

| Brass | * | X |

| Titanium | * | X |

| Bare Metal | * | X |

video

photo

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)